RaySense Pipeline Protection System

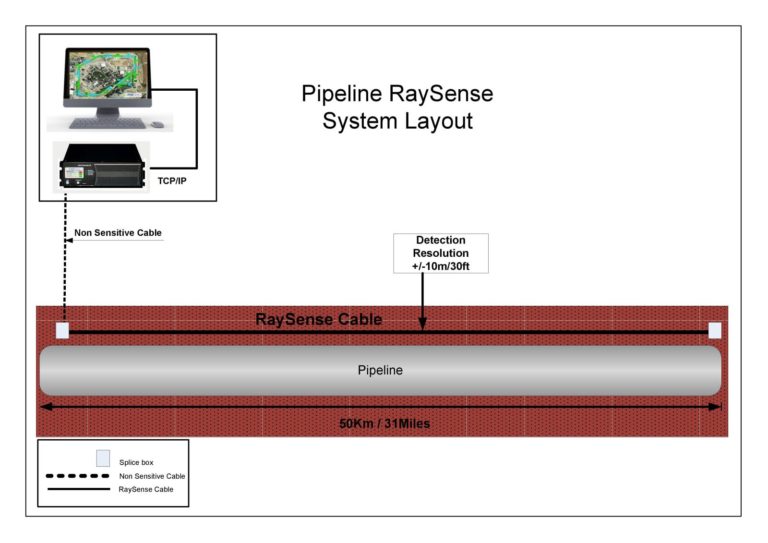

A single pipeline security system protects up to 50km per APU against Third-Party Interference (TPI), Leaks, Illegal tapping attempts and unauthorised excavation.

- All-In-One – Same unit and cable protect against leaks, TPI and excavation

- The world’s first locating, ultrasonic distributed vibration sensor (DVS)

- Up to 50km/31miles per processing – no limit in network.

- Locate a TPI, tapping or leaking event to ±10M/±30ft resolution over the entire length.

- Signature based detection – Wide range frequency detection, 3Hz to 500 kHz

- No electronics or power required in the field.

- IP based remote control and monitoring with 3rd party integration.

With the long fiber optic monitoring capabilities the RaySense provides 100% perimeter coverage for long range applications with no gaps between sensors, the cable is the sensor.

The pipeline leak detection capability is based on acoustics which allows the cable to detect without any physical movement of the cable, it can be buried in any type of ground or soil and detect even a 0.5mm hold in a high pressured pipe.

Distributed Vibration Sensor (DVS) Pipeline Protection System is effective in the prevention of oil spills and/or gas explosions due to its unique ability to detect, locate and classify vibrations caused by physical activity (such as third party interference – TPI), while simultaneously monitoring for early-stage leaks, along the entire length of the pipeline in real time. It is also capable of early detection and location of dynamic geological hazards, such as landslides, or excavating activity (by equipment or hand) anywhere within the vicinity of a pipeline, and in many cases prior to the excavating operation within the right-of-way.

The RaySense system can be employed for real-time precise detection and location of dangerous events to pipelines. The core RaySense technology acts as a continuous microphone designed to “monitor” over a quasi-DC to 500 kHz bandwidth, to very distinctive frequencies generated by TPI and leak events, while discriminating between normal and ambient conditions.

Furthermore, with additional channels, the RaySense system provides reliable perimeter security for processing plants, distribution or intermediate stations and storage sites.

Return on your investment

Utilizing fiber-optic cable, the system is the most economically competitive technology currently available for long distances. Requiring only a single alarm processing unit (APU) to cover up to 50km/31 Miles of pipeline, combined with a rugged fiber-optic sensing cable, results in the most cost-effective solution for large perimeters.

In some application the RaySense system can utilize the pre-exsiting communication cable for detection.

Applications:

- Crude oil pipelines

- Refined product lines – gasoline, fuel, chemicals

- Gas pipelines

- Water pipelines

- Underground power

Or any pipeline that needs protection

Advantages of RaySense Fiber Optic Sensor System

• 3RU, 19-inch, rack-mount, processing unit (APU) doesn’t need temprature controlled room, reduces costs and electronics footprint in control room

• Hardware based on dedicated programmable microprocessor and DSP chips ensures fast stable performance

• The longest range precision monitoring capability with a single APU covering perimeters up to 50km/31miles, reducing infrastructure requirements; daisy-chaining controllers provide unlimited reach

• Tightly integrates with the RBtec Vidalert Command and Control System enabling remote and centralized monitoring and control of the entire system

• Capable of pinpointing intrusion over the entire length of the perimeter to within ±10M/±30ft with unlimited zones

• Immune to electromagnetic, lightning and radio frequency interference (EMI/RFI) ensures reliable operation in challenging environments

• No power/communications requirements in the field reduce infrastructure costs

• Self-calibrated each hour; requires almost no maintenance and ensures system uptime

• TCP/IP interface allows non-proprietary communications using readily available network equipment

• Low energy consumption – produces nominal heat, eliminating need for air conditioned racks

• Field upgradeable firmware ensures equipment software can be brought up to the latest version on the spot, even over TCP/IP